Hydraulic Pump Station

1. Hydraulic pumping stations

Hydraulic Station, Hydraulic System

A hydraulic station, also known as a hydraulic pump station, is an independent hydraulic device. It supplies oil according to step-by-step requirements. And control the direction of hydraulic oil flow, pressure and flow, applicable to the host and the hydraulic device can be separated from a variety of hydraulic machinery. Users after the purchase as long as the hydraulic station and the host of the actuator (cylinder or oil motor) connected to the oil pipe, hydraulic machinery can realize a variety of prescribed actions and work cycle.

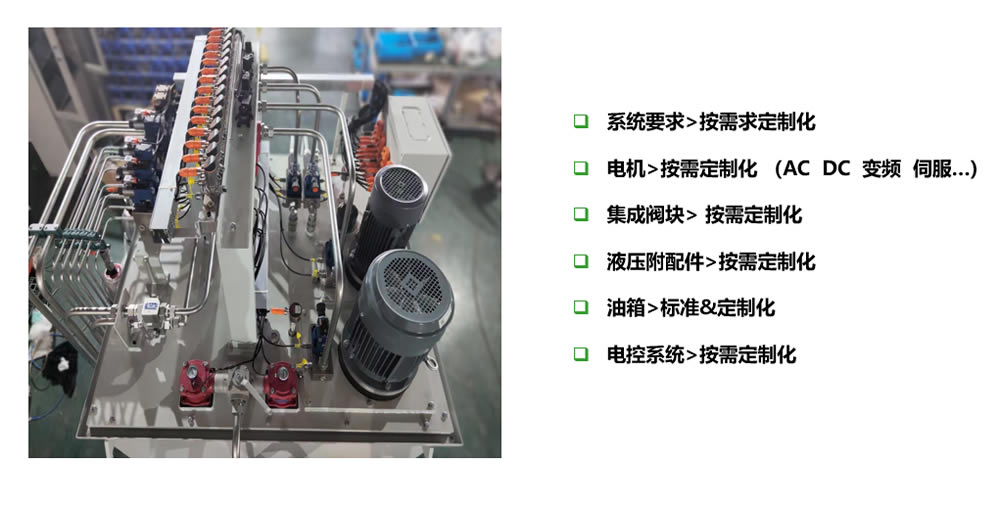

Products

Hydraulic station structure composition

Hydraulic station, also known as hydraulic pump station, is an independent hydraulic device. It supplies oil according to step-by-step requirements. And control the direction of hydraulic oil flow, pressure and flow, applicable to the host and the hydraulic device can be separated from a variety of hydraulic machinery. Users after the purchase as long as the hydraulic station and the host actuators (cylinders or oil motors) connected to the oil pipe, hydraulic machinery can realize a variety of prescribed actions and work cycle.

Hydraulic station is by the pump device, integrated block or valve combination, tank, electrical box combination.

The function of each component is:

Pump device – equipped with a motor and oil pump, is the power source of the hydraulic station, the mechanical energy into the hydraulic oil pressure energy.

Integration block-assembled by hydraulic valve and channel body. The hydraulic oil to implement the direction, pressure and flow regulation.

Valve group – plate valve mounted on the plate, the plate after the pipe connection, and the integrated block function is the same.

Oil tank – plate welded semi-closed container, also equipped with oil filter, air filter, etc., used for oil storage, oil cooling and filtration.

Electrical box – there are two types. A set of external lead terminal board; a configuration of a full set of control appliances.

Hydraulic station working principle

Hydraulic station, also known as the hydraulic pump station, motor driven oil pump rotation, pump from the oil tank after sucking oil, the mechanical energy into hydraulic oil pressure energy, hydraulic oil through the integrated block (or valve combination) by the hydraulic valve to achieve the direction, pressure, flow rate adjustment through the external pipeline transmission to the hydraulic machinery cylinders or oil motors, thereby controlling the direction of the change in the liquid motive force, power and speed of the speed of the change to promote the various hydraulic Hydraulic machinery to do work.

Hydraulic station is an independent hydraulic device, it according to the driving device (host) requirements for oil supply, and control the direction of oil flow, pressure and flow, it applies to the host and the hydraulic device can be separated from a variety of hydraulic machinery, driven by the motor oil pump rotation, the pump from the oil tank after the oil pumping, the mechanical energy into the hydraulic oil pressure energy.

After purchase, as long as the hydraulic station and the host on the implementation of the actuator (cylinder and oil motor) with oil pipe connection, hydraulic machinery can realize a variety of prescribed actions, work cycle.

Product Parameters